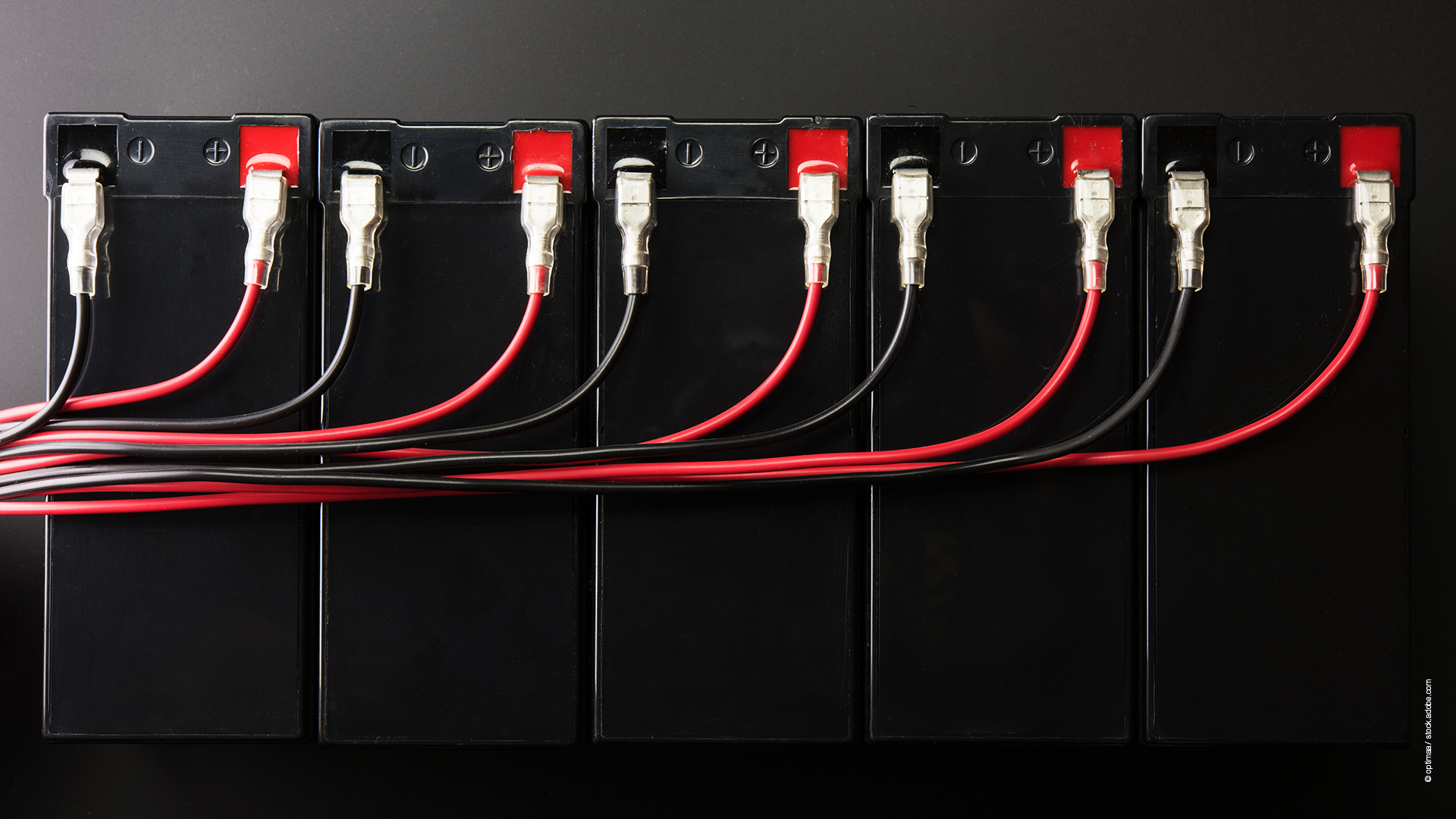

If manufacturers pay too little attention to battery quality, it can affect battery performance and safety. Defective batteries can damage devices. In the worst-case scenario, it may even cause fires or explosions and thus, personal injury as well. This is why an increasing number of consumers are also looking out for the independent VDE mark on batteries.

Developments in electromobility and increased demand for wireless electric devices increase the demand for powerful and reliable batteries.

Thanks to lithium-ion batteries and other technologies, an increasing number of electrical products that are currently tethered to a power cable can operate "wirelessly" in the future.

The VDE Institute has established a modern testing center for testing batteries.

VDE Experts can test all types of batteries and storage systems in this test center. They can also perform this testing during the development phase.

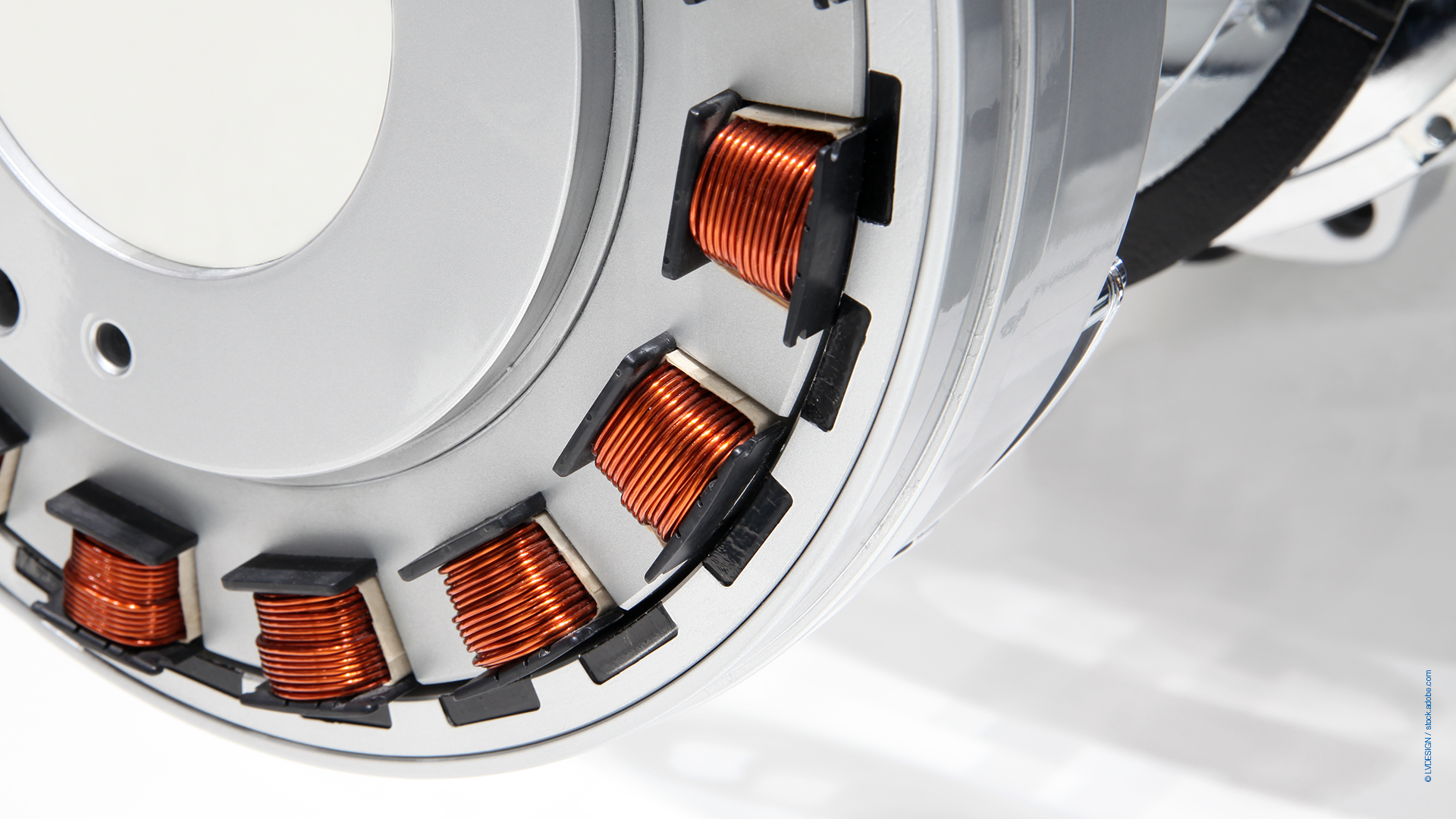

High demands are placed on the safety and reliability of batteries worldwide. As a result, the experts at the VDE Institute con[1]duct extensive testing. We perform chemical analyses and tests related to compliance of requirements according to Battery.

Directive 2006/66/EC and assess the corrosion resistance. The effects of shocks,

vibrations, vacuum, squashing, piercing, freefall and impact on batteries are tested

during mechanical tests. A climate chamber is used to test if batteries can withstand

various thermal conditions (climate test, temperature shock, moisture).

Demand for batteries along with stationary and mobile storage systems in the renewable energies sector is also increasing worldwide.

The market for energy storage systems is currently unfolding very dynamically, primarily in North America, Europe and the Asia-Pacific region. With laboratories in Asia, Germany and the USA, the VDE is expanding its testing and certification product portfolio for energy storage products and systems on an international scale.