Trade fair innovationFrame

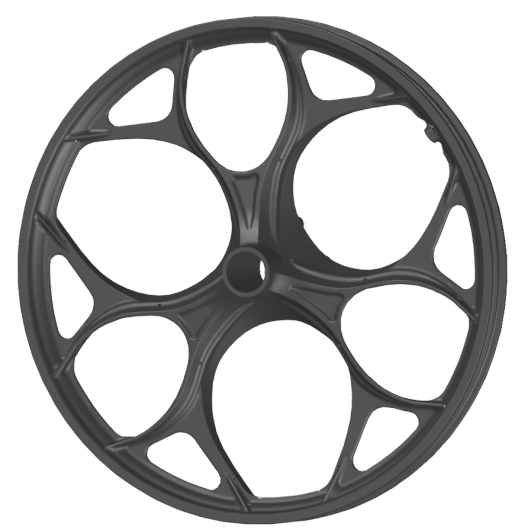

Hollow bicycle frame made of carbon fiber-reinforced thermoplastic, manufactured by Weber Fibertech GmbH.

creative

Fiber-reinforced thermoplastic can be used to create designs that clearly stand out from the market. The material allows creativity and also opens up the possibility of integrating special functions in an attractive way.

economical

The bicycle frame is manufactured using the injection molding process with water injection. This process enables the production of hollow plastic frames in which the use of material and weight is optimized. The combination of short cycle times and a 100% degree of automation form the basis for economical large-scale production in Germany.

sustainable

Thermoplastics become soft and malleable when heated and harden again when cooled without changing their chemical structure. This means that bicycle frames made from thermoplastics are 100% recyclable.

If you look at the CO² emissions in the production of thermoplastics, they have nothing to hide here either: compared to aluminum, CO² emissions are reduced by over 80%. In addition, there are short delivery routes for both the raw materials sourced in Europe and the finished frames to the European market.

www.fibitec.com

www.weber-fibertech.com