Vehicle Tests

Description

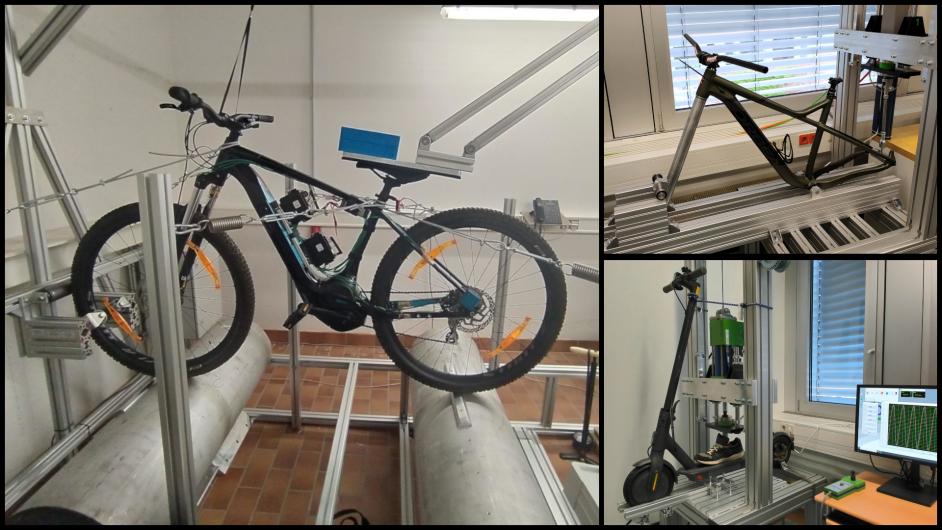

A roller test bench based on DIN 79010 is available for testing complete vehicles. This allows the durability to be tested under controlled conditions with realistic operating loads in a short time. The drum diameter is 400 mm and the speed can be continuously adjusted from 0 to 45 km/h. The load is varied by differently designed impact bars. Vehicles with a wheelbase of 1 m to 2 m, a track width of up to 1 m (single or multi-track) and a maximum weight of 280 kg can be tested.

Individual parts and vehicle components can be tested using dynamic testing machines. Modular test frames made of aluminum profiles are used for positioning and fixing the test specimens. Thanks to the flexibly configurable test area, larger components such as wheels or complete bicycle frames can also be subjected to static and dynamic loads. The force is applied by one pneumatic and one electric cylinder. These can be used to apply forces of up to 7.5 kN, test frequencies of up to 10 Hz and strokes of up to 300 mm. The cylinders can be used both in single-axis operation and combined in multi-axis operation. In addition to testing in accordance with common test standards, individual test sequences and setups, tests using recreated measured signals and stiffness measurements are also possible.